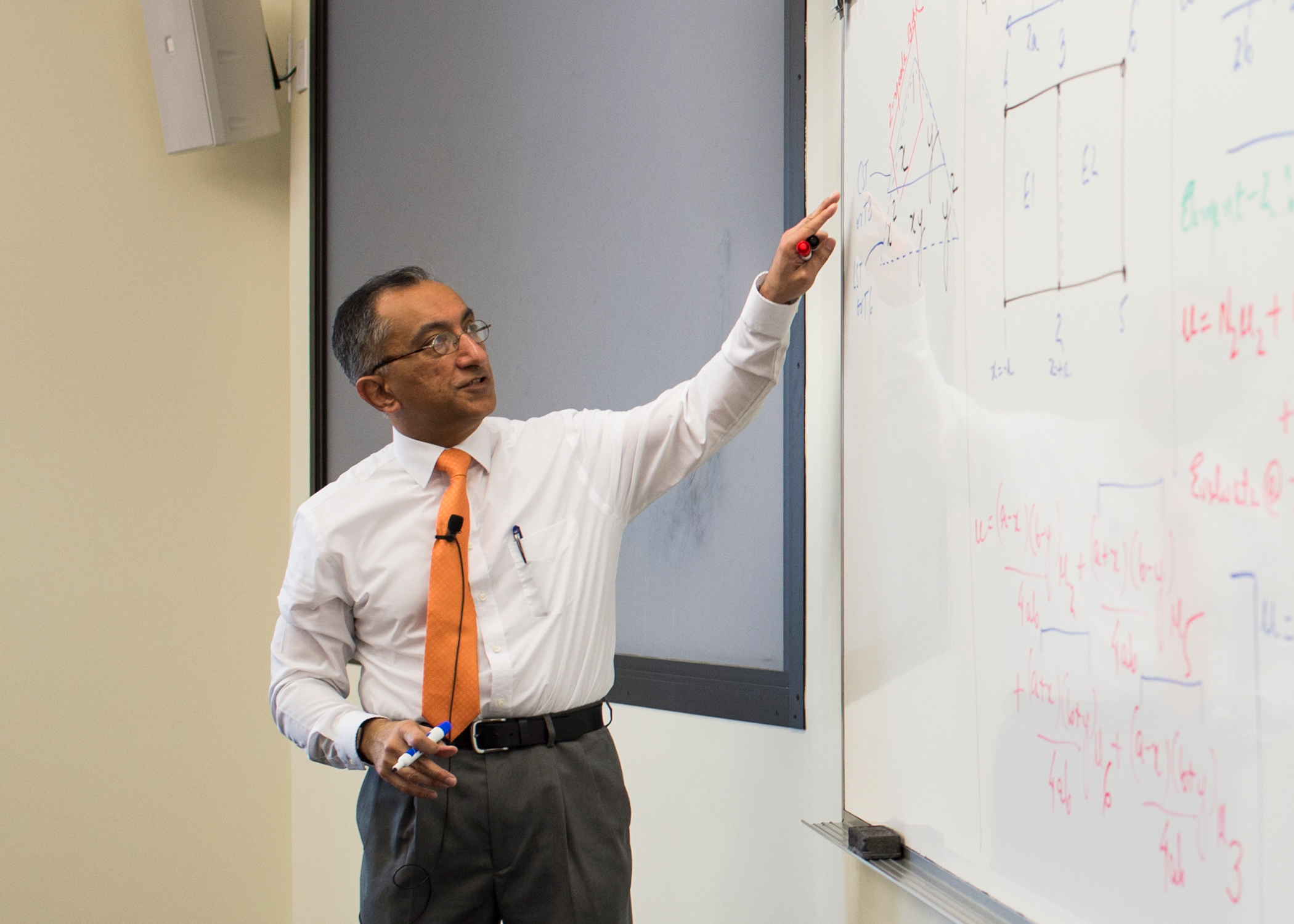

Pradeep Lall

MacFarlane Endowed Distinguished Professor and Alumni Professor, Mechanical Engineering

Courtesy Joint Appointment in Electrical and Computer Engineering

Courtesy Joint Appointment in Finance

Technical Council Asset Monitoring and Automotive TWGs of NextFlex

Director, NSF-CAVE3 Electronics Research Center (CAVE3)

Phone: 334-844-3424

Fax: 334-844-3450

Email: lall@auburn.edu

Office: 1438 Wiggins Hall

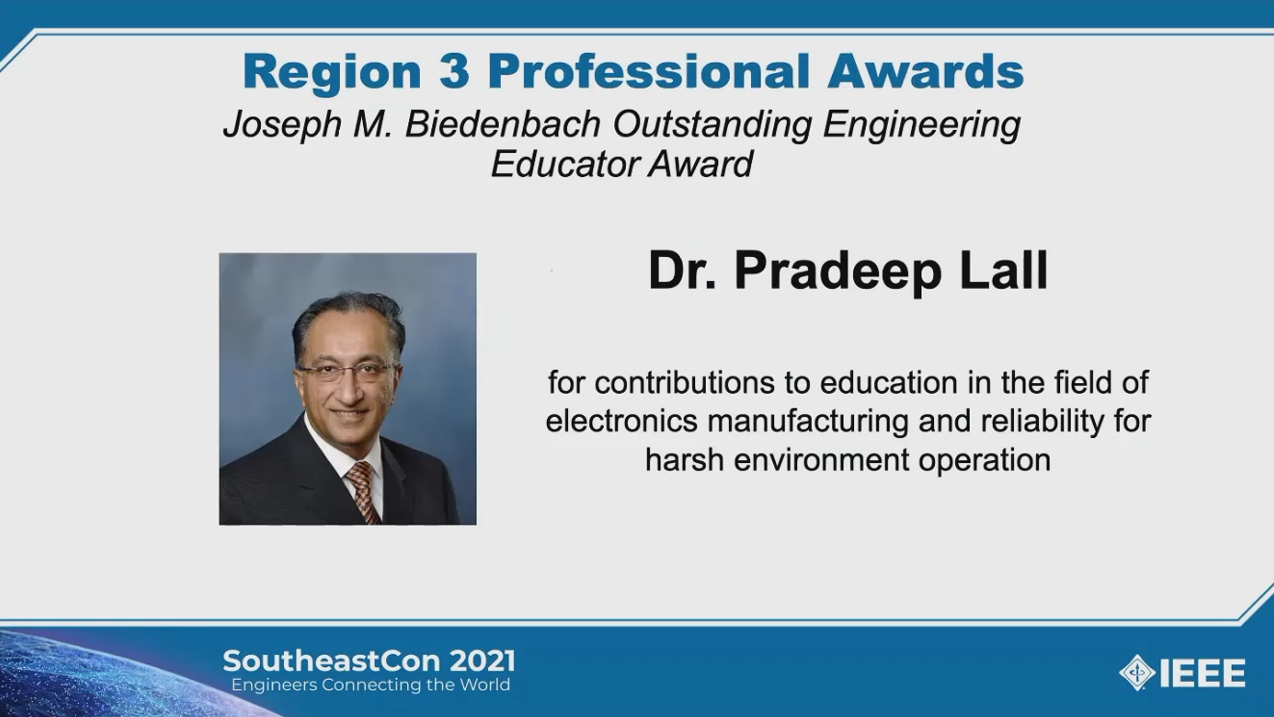

Pradeep Lall is the MacFarlane Endowed Distinguished Professor and Alumni Professor with the Department of Mechanical Engineering and Director of the NSF-CAVE3 Electronics Research Center at Auburn University. He holds Joint Courtesy Appointments in the Department of Electrical and Computer Engineering and the Department of Finance. He is a member of the technical council and academic co-lead of automotive and asset monitoring TWGs of NextFlex Manufacturing Institute. He is the author and co-author of 2-books, 15 book chapters, and over 900 journal and conference papers in the field of electronics reliability, manufacturing, safety, test, energy efficiency, and survivability. Dr. Lall is a fellow of the ASME, a fellow of the IEEE, a fellow of the NextFlex National Manufacturing Institute, and a fellow of the Alabama Academy of Science. He is recipient of the SEMI R&D Achievements Award for landmark contributions to Additive Printed Electronics, ASME Avram Bar-Cohen Memorial Medal, IEEE Biedenbach Outstanding Engineering Educator Award, Auburn University Research Advisory Board’s Advancement of Research and Scholarship Achievement Award, IEEE Sustained Outstanding Technical Contributions Award, NSF-IUCRC Association’s Alex Schwarzkopf Award, Alabama Academy of Science Wright A, Gardner Award, IEEE Exceptional Technical Achievement Award, ASME-EPPD Applied Mechanics Award, SMTA’s Member of Technical Distinction Award, Auburn University’s Creative Research and Scholarship Award, SEC Faculty Achievement Award, Samuel Ginn College of Engineering Senior Faculty Research Award, Three-Motorola Outstanding Innovation Awards, Five-Motorola Engineering Awards, and over Fifty Best-Paper Awards at national and international conferences. Dr. Lall has served in several distinguished roles at national and international level including serving as member of National Academies Committee on Electronic Vehicle Controls, Member of the IEEE Reliability Society AdCom, IEEE Reliability Society Representative on the IEEE-USA Government Relations Council for R&D Policy, Chair of Congress Steering Committee for the ASME Congress, Member of the technical committee of the European Simulation Conference EuroSIME, Associate Editor for the IEEE Access Journal, and Associate Editor for the IEEE Transactions on Components and Packaging Technologies. Dr. Lall is the founding faculty advisor for the SMTA student chapter at Auburn University and member of the editorial advisory board for SMTA Journal. He received the M.S. and Ph.D. degrees in Mechanical Engineering from the University of Maryland and the M.B.A. from the Kellogg School of Management at Northwestern University.

Selected Awards and Honors

- SEMI R&D Achievements Award (2023)

- ASME Avram Bar-Cohen Memorial Medal (2022)

- IEEE Biedenbach Outstanding Engineering Educator Award (2020)

- Inducted as Professional Member of IEEE-Eta Kappa Nu (IEEE-HKN) International Honor Society of IEEE (2019)

- John and Anne MacFarlane Endowed Distinguished Professor (2019)

- Fellow of the NextFlex National Manufacturing Institute on Flexible Electronics (2019)

- Auburn University Research Advisory Board’s Advancement of Research and Scholarship Achievement Award (2018).

- IEEE Sustained Outstanding Technical Contributions Award (2018)

- NSF-IUCRC Alex Schwarzkopf Prize for Technology Innovation (2016)

- Samuel-Ginn College of Engineering Senior Faculty Research Award (2016)

- Wright A. Gardner Award, Alabama Academy of Sciences (2016)

- IEEE-CPMT Exceptional Technical Achievement Award (2014)

- Fellow of the Alabama Academy of Sciences (2014)

- ASME Applied Mechanics Award, American Society of Mechanical Engineers, (2013)

- Recipient of Member of Technical Distinction Award, Surface Mount Technology Association, SMTA (2013).

- Creative Research and Scholarship Award, Auburn University (2013)

- SEC Faculty Achievement Award (2013)

- Fellow of IEEE (2012)

- Member, National Academies Committee, Electronic Vehicle Controls and Unintended Acceleration (2010)

- Fellow of the ASME, (2008).

Comments

3 responses to “Biography”

[…] Pradeep Lall, John and Anne MacFarlane professor of mechanical engineering, has received a top award from the National Science Foundation’s Industry/University Cooperative Research Centers program. […]

[…] Pradeep Lall, John and Anne MacFarlane professor of mechanical engineering, has received a top award from the National Science Foundation’s Industry/University Cooperative Research Centers program. […]

[…] Biography […]